What are the skills of cutting the big saw blade 02?

Dora Zhang

2022-07-26 12:36:53

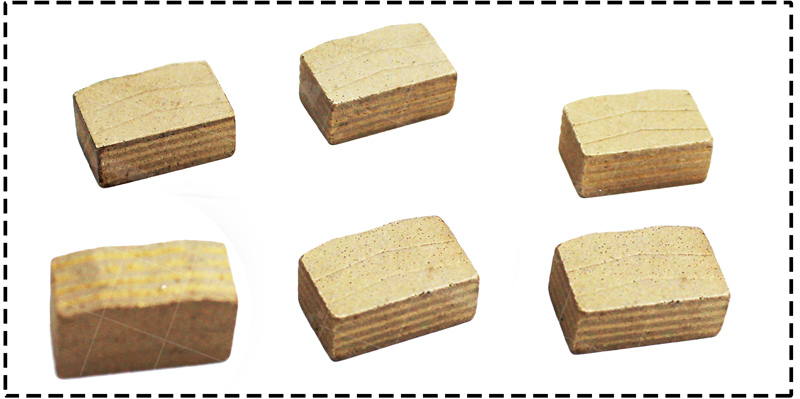

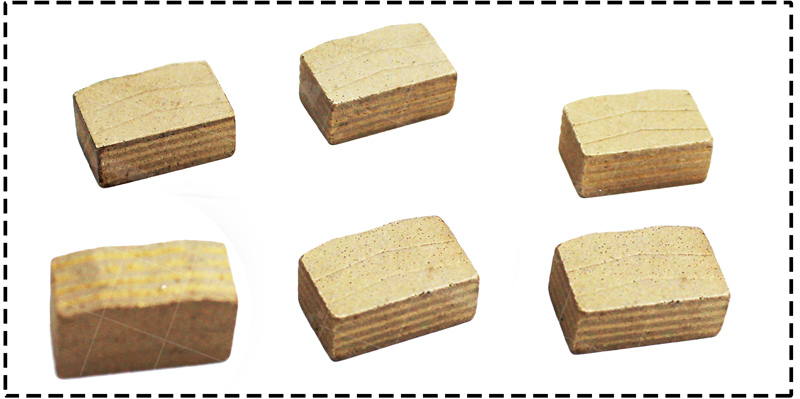

1. During the idling process of the saw blade, the saw blade shakes stably, and the swing amplitude is small and stable. In this case, it can be sawed in, and it is not allowed to cut directly, which is easy to cut the stone; When cutting stops, it is not allowed to clamp the saw blade in the stone.tt shape diamond cutting segment .The saw blade must be raised to a high position to prevent the saw blade from being stuck by the swing of the waste material and damage to the saw blade.

2. In the process of cutting, if you find that the waste material shakes, you must stop cutting immediately, and then cut after you fix the waste material again and make sure that it will not shift or swing.

3. When multi saw blade diamond cutting segment cutting the block, it is found that the saw blade has obvious deceleration, and even the phenomenon of knife clamping occurs. It may be due to belt slipping, nut loosening, too deep knife cutting, too fast knife walking speed and other reasons, which should be adjusted in time.

4. Linear speed is also known as cutting speed. The faster the cutting speed is, the faster the consumption of diamond saw blade will be, and the shorter the service life will appear. The slower the cutting speed is, the slower the consumption of the diamond saw blade is, and the longer the service life of the saw blade will be obviously felt. Therefore, generally, the service life of sharp saw blades is not long, while the service life of non sharp saw blades is OK.

2. In the process of cutting, if you find that the waste material shakes, you must stop cutting immediately, and then cut after you fix the waste material again and make sure that it will not shift or swing.

3. When multi saw blade diamond cutting segment cutting the block, it is found that the saw blade has obvious deceleration, and even the phenomenon of knife clamping occurs. It may be due to belt slipping, nut loosening, too deep knife cutting, too fast knife walking speed and other reasons, which should be adjusted in time.

4. Linear speed is also known as cutting speed. The faster the cutting speed is, the faster the consumption of diamond saw blade will be, and the shorter the service life will appear. The slower the cutting speed is, the slower the consumption of the diamond saw blade is, and the longer the service life of the saw blade will be obviously felt. Therefore, generally, the service life of sharp saw blades is not long, while the service life of non sharp saw blades is OK.

5. The cutting speed is also called the cutting depth.Stone block cutting diamond segments. The deeper the cutting depth is, the saw blade will slip in the process of cutting stone. Once the saw blade slips, the cutting will shift and the stone will not be cut. Therefore, appropriately reducing the cutting depth can obviously solve this problem.